GORAND Consulting Services Pty Ltd is a privately owned Electrical, Automation, and Network Engineering Consultancy company, based in Newcastle, New South Wales (NSW), Australia.

The company was established in 1994 to offer quality, innovative, and cost effective Electrical and Automation Engineering services to primarily mining and manufacturing industries. During the 20+ years that the company has been in business, projects have now been successfully completed in an extremely diverse range of industry sectors, ranging from mining and mineral processing, to steel, aluminium, & copper refining, food and pharmaceuticals, manufacturing, defense (air force and navy), and residential & commercial building construction, just to name a few.

What We Do

GORAND Consulting Services specialises in the Design, Programming, Installation, Commissioning, Documentation, and Troubleshooting of Automation & Process Control Systems, and Computer & Communication Networks.

In addition to the above, our company also provides general Electrical Engineering, Technical Documentation, Training, and Project Management services.

What are Automation Systems ?

Automation Systems are intelligent Control Systems that control a piece of machinery, a production process, or an entire plant, with minimal human intervention (thus providing an efficient and safer working environment).

Industrial Automation Systems

Industrial Automation Systems typically combine Programmable Logic Controllers (PLC's) or Programmable Automation Controllers (PAC's) and desktop or industrial computers running Supervisory Control And Data Acquisition (SCADA) software, to control some form of process or machinery.

The PLC's and PAC's provide the physical control of the machinery. They gather information from various sensors such as limit switches, pushbuttons, temperature & pressure sensors, and level probes, and use this information to control various items such as motors, conveyors, pumps, valves, and lights.

The SCADA software running on the computer(s) allows Plant Operators to interact with the PLC / PAC system. By using dashboards, graphics, and mimics on the computer display to represent the process and machinery under control, the Operator can use a keyboard, mouse, or other pointing device (including a touch screen) to select a pump for example, and then Start or Stop this pump by simply "clicking" on a Start or Stop button associated with it. By using this method pumps and other equipment located several hundred meters, or even many kilometers or more away, can be controlled and monitored from the one central location.

The SCADA software also allows a great deal of information to be gathered about the operational condition of the plant and machinery. This information can be summarized and printed out automatically on a specific time basis, such as end of shift, end of day, etc, so as to provide management with up to date information on which to base decisions.

Communication Networks

Communication Networks form the backbone of any automation system. Information is passed from device to controller, from controller to controller, and from controller to supervisory system, over these networks.

Original communication networks were based on propriety systems developed by large technology or industrial automation companies.

These days the vast majority of communication networks are Ethernet (global standard) based, including many industrial networks.

Originally Ethernet utilised the Internet Protocol Version 4 (IPv4) protocol. Now, next generation IPv6 is commonplace.

Wireless networks now compete with traditional wired networks, in both industrial and commercial settings.

Homes and businesses are connected to the Internet over Broadband or WiFi networks (both are Ethernet based networks).

The Internet Of Things (IoT), which generally refers to every device connecting to each other (be it sensor, controller, computer, phone, tablet, etc), is the next step. This global interconnectivity of devices is well underway, and again is Ethernet based !

Network Security has also become a major issue, for all types of network installations. Unauthorised access into networks can cause significant disruption, as well as major financial impacts, to an organisation or broader group of people.

Correct network design for the particular situation, in combination with ongoing monitoring and maintenance, can significantly reduce the chances of an issue arising.

We have engineers who are certified by the world's leading Ethernet networking equipment provider, Cisco Systems, who can assist with all your networking needs.

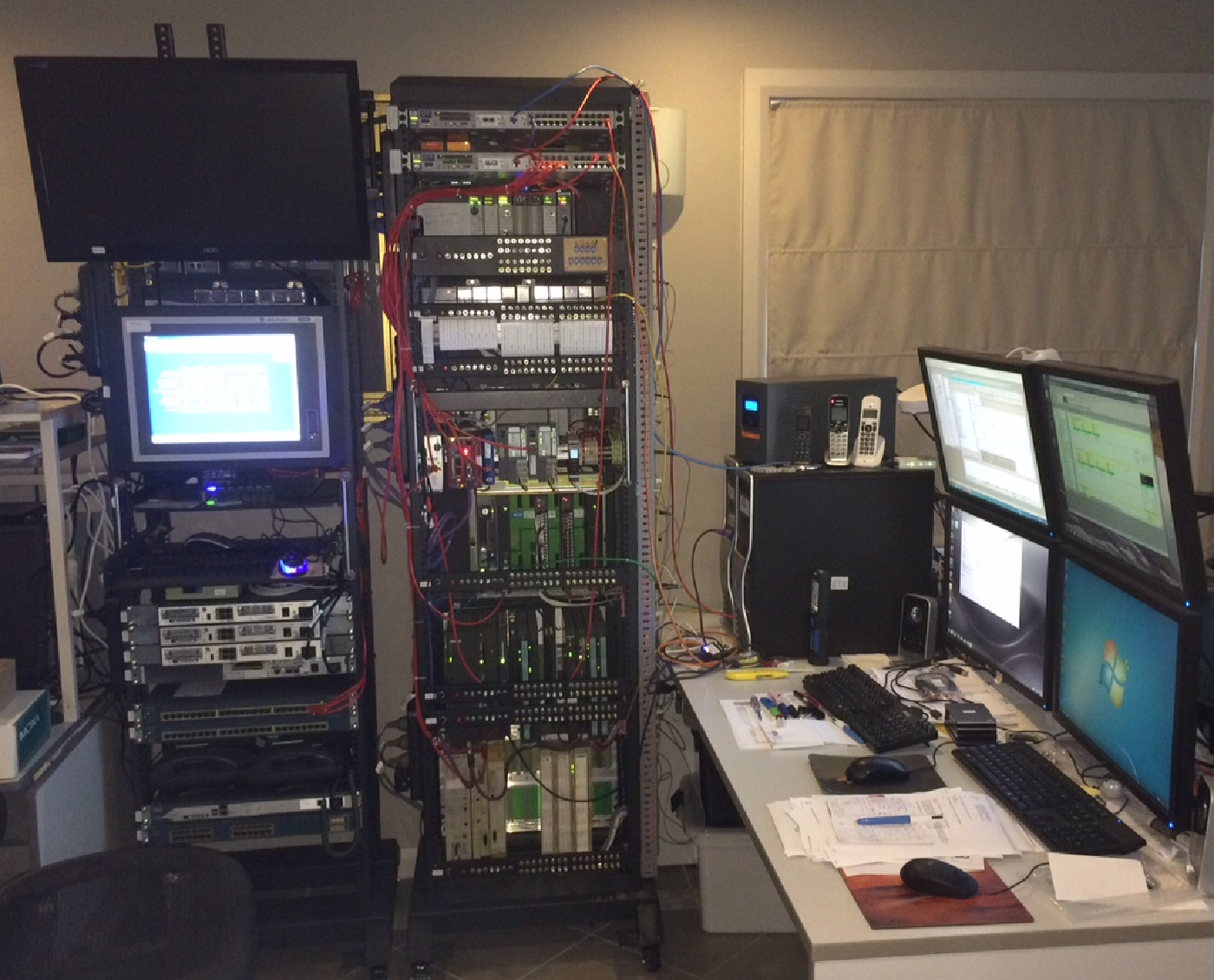

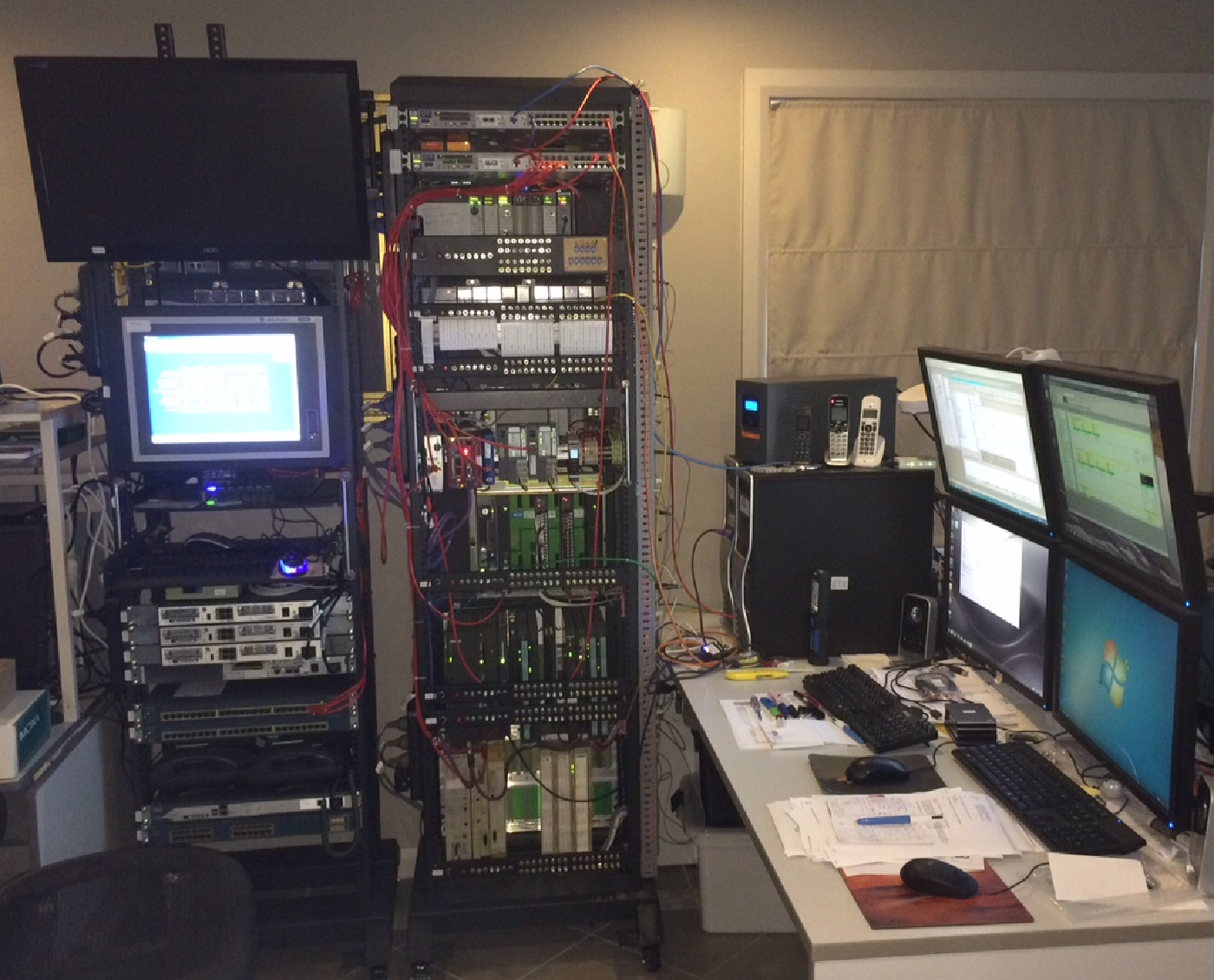

Extensive In-house Development & Testing Equipment

We have expanded our capabilities to include full in house development and testing of automation and communication systems on actual physical PLC / PAC / SCADA and Networking equipment. This allows us to provide a extensively tested product prior to any site installation, thus vastly reducing site installation and commissioning timeframes and costs. The development and test rig also allow for extensive hands on training to be carried out in any control and/or networking systems that are developed, or for general PLC, PAC, SCADA, and Network Systems training.